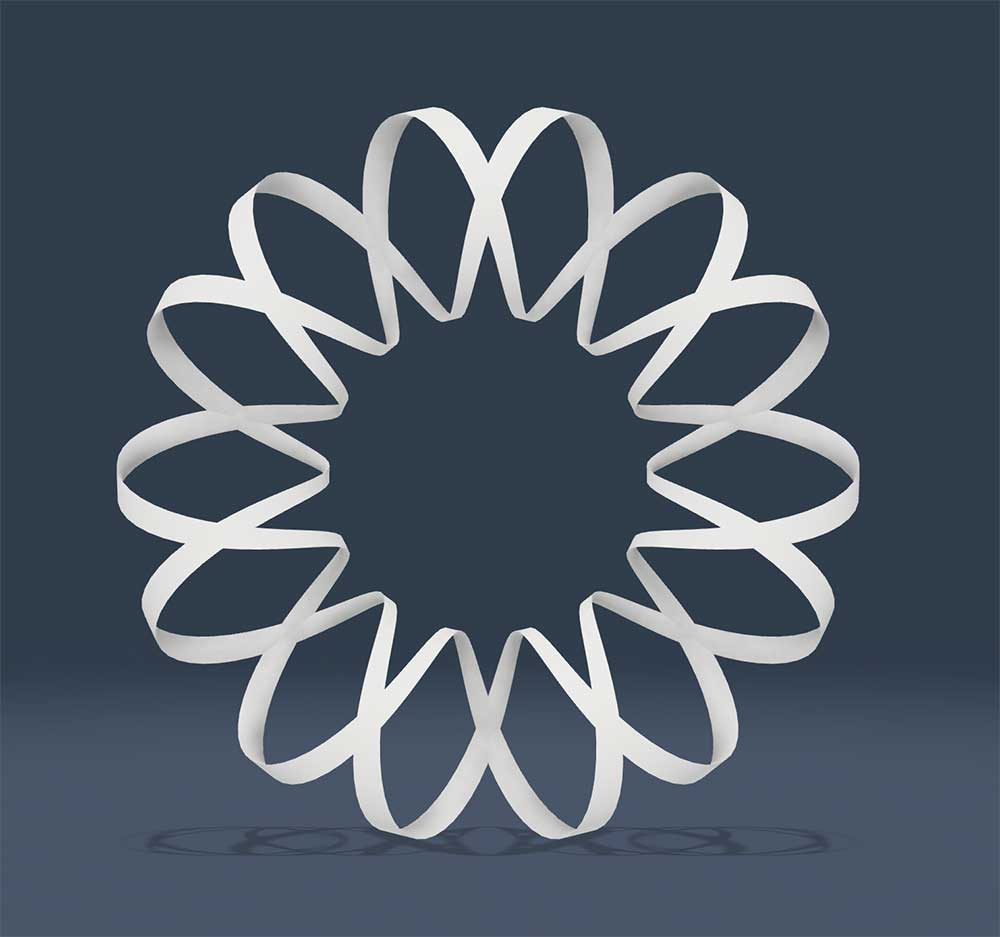

Wreaphs at Blackhorse Workshop Christmas Market

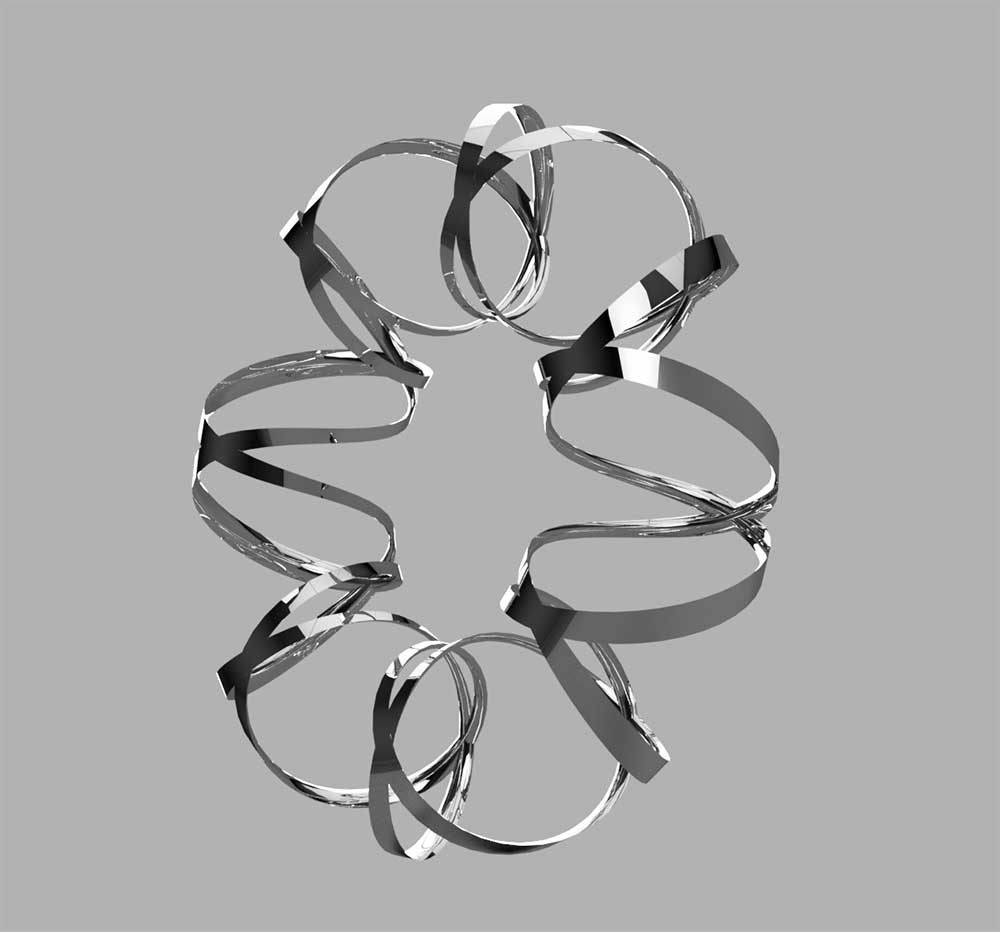

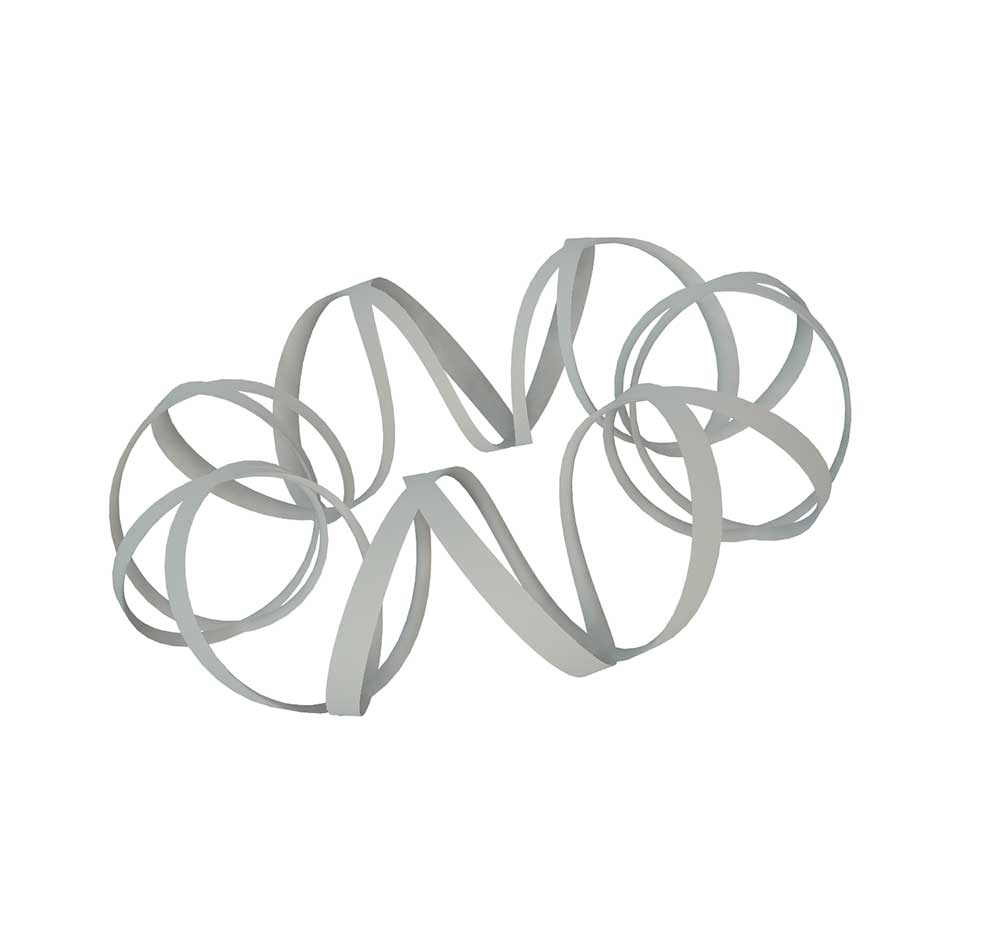

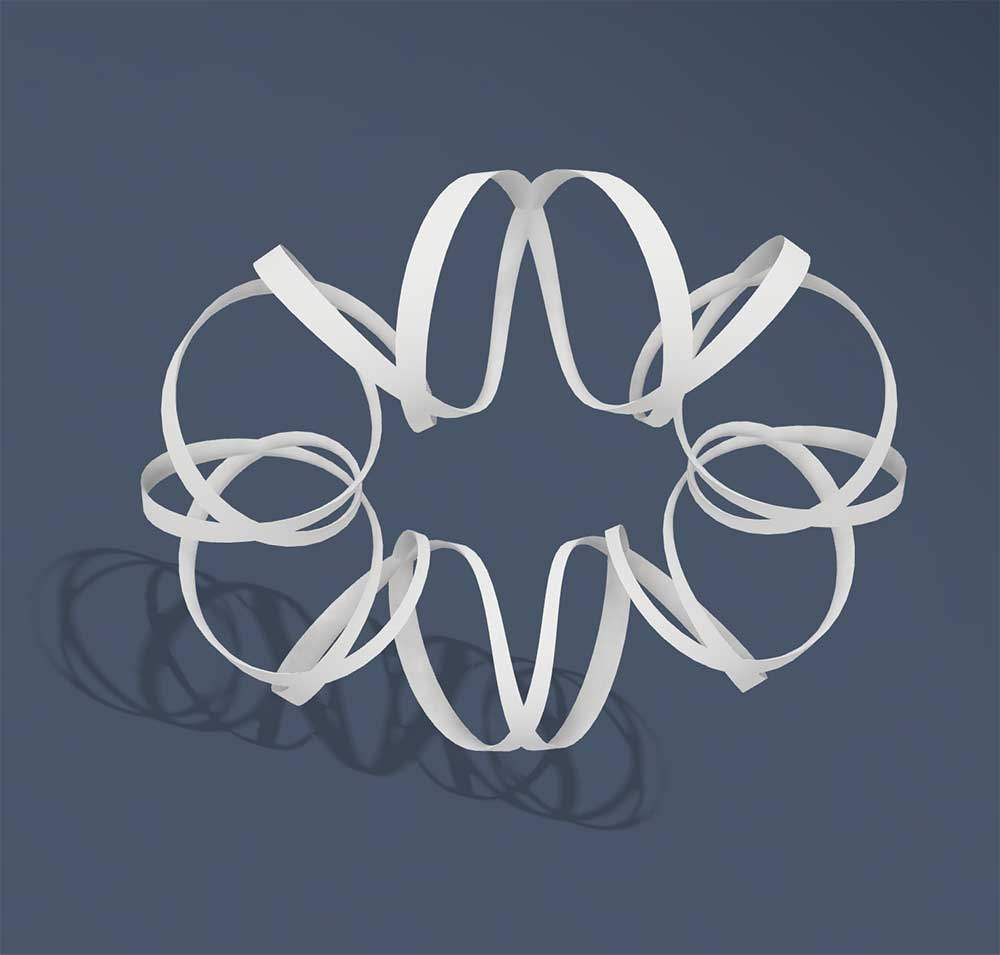

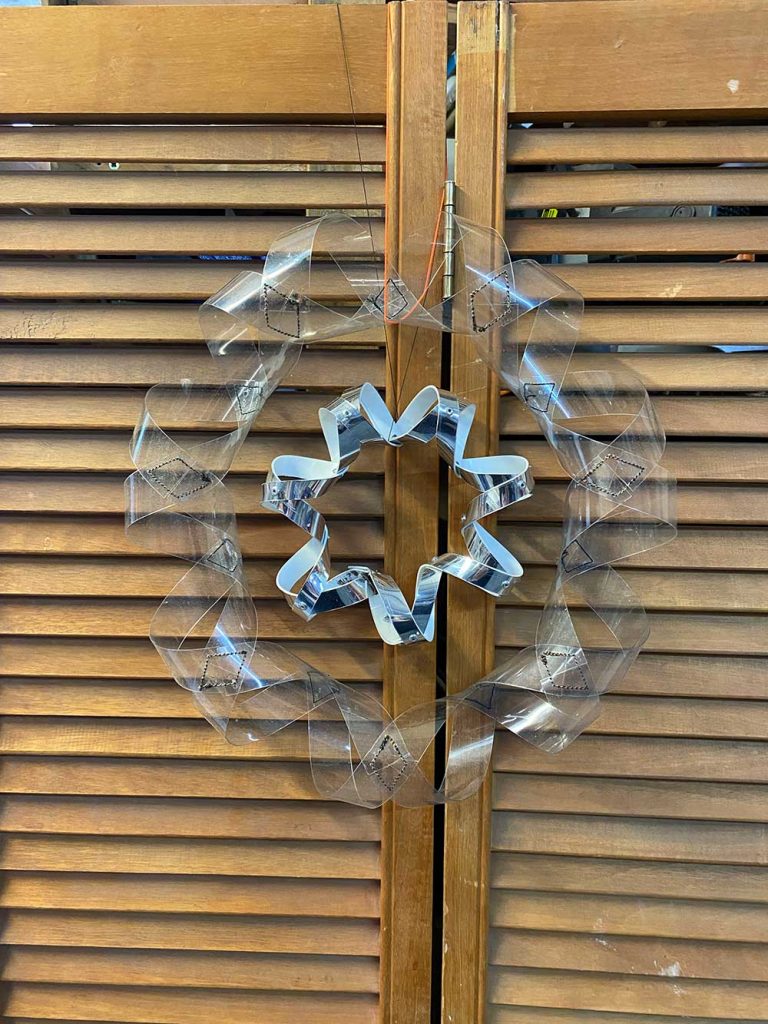

A new take on the traditional wreath. And it’s made of recycled plastic. Also a fixation on two helical strips wrapped around a toroidal void crossing each other in opposite directions.

This sunflower was the inspiration.

I could not think of anything else once I stumbled upon this shape.

On a walk, I suggested using recycled plastic as a material to to a friend who was about to start a wreath making course and she was simply dumbfounded. Did not, could not, would not respond. Then the lights changed and we walked on. Was it such a terrible idea? Did I blaspheme?

Now I was stuck with the idea of recycled plastic wreaths! Why not? Really, why not?!

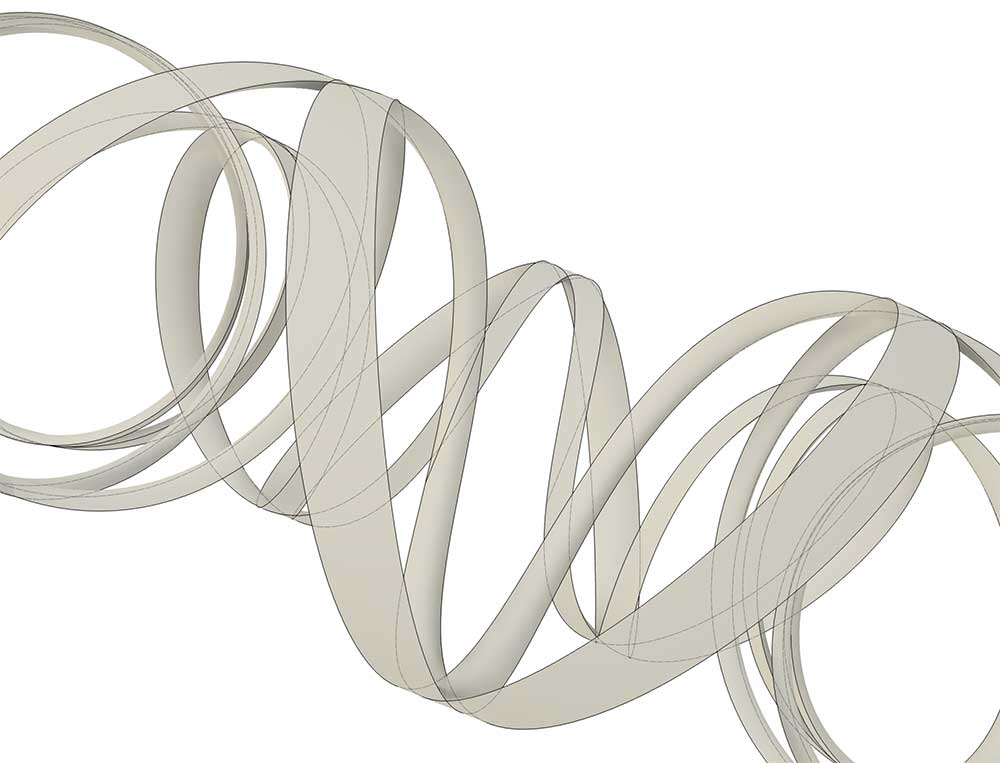

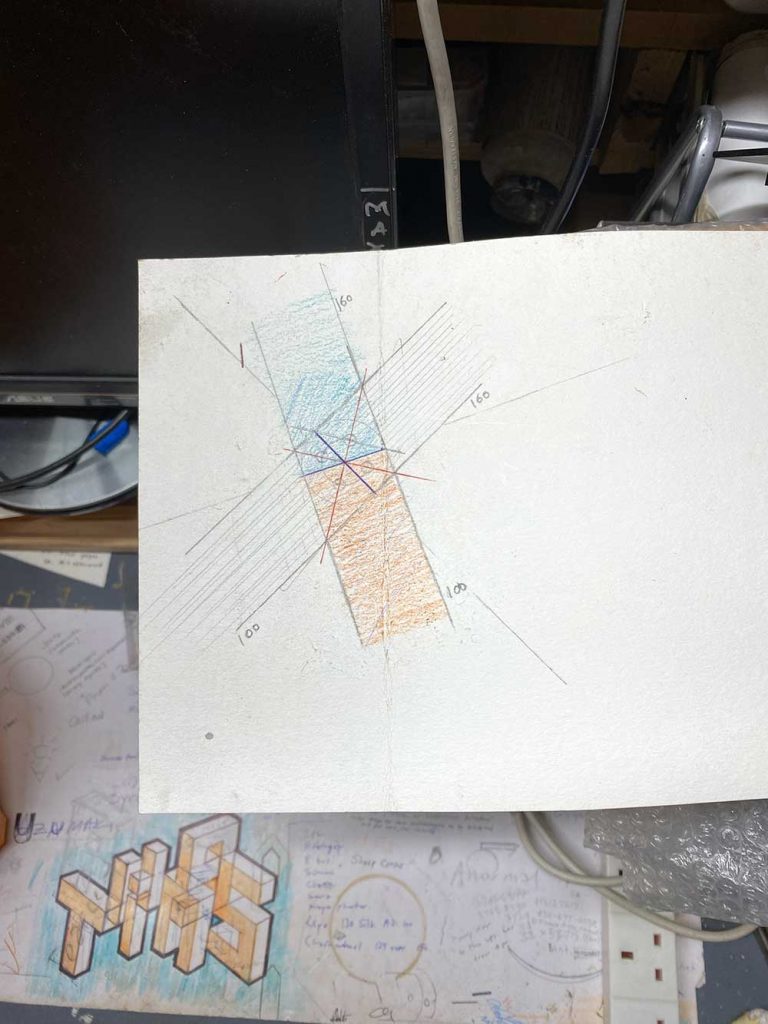

It’s really hard to get the pieces to stay in the right place. Good amount of stubbornness supported by engineering. I sketched out the idea on paper but it took so long for me to find the time to model it in software that I already worked out the whole lifecycle of the thing. Fusion 360 helped me to decide the number of rotations of the helix (7) and the width of the strips.

Finally, I found the time to put it together. One evening, I rocked up to the workshop and gathered my materials, made a cup of tea, checked my emails, kinda took it slow and told myself to enjoy this. A few quick wreaths and I could go home and rest.

To my surprise and horror, the process was so very painstakingly difficult. How could I be so arrogant! The wreath gods were laughing at me. And I imagined the face of my friend who couldn’t even honour my utterance of recycled plastic wreaths idea with a nod of her head, laughing viciously. Plus I had been showing everyone my lovely idea of two strips spiralling around each other seven times and producing a torus that was made of that noblest of all materials: Recycled Plastic. I could not go back home before making at least some progress.

Failed. Nothing.

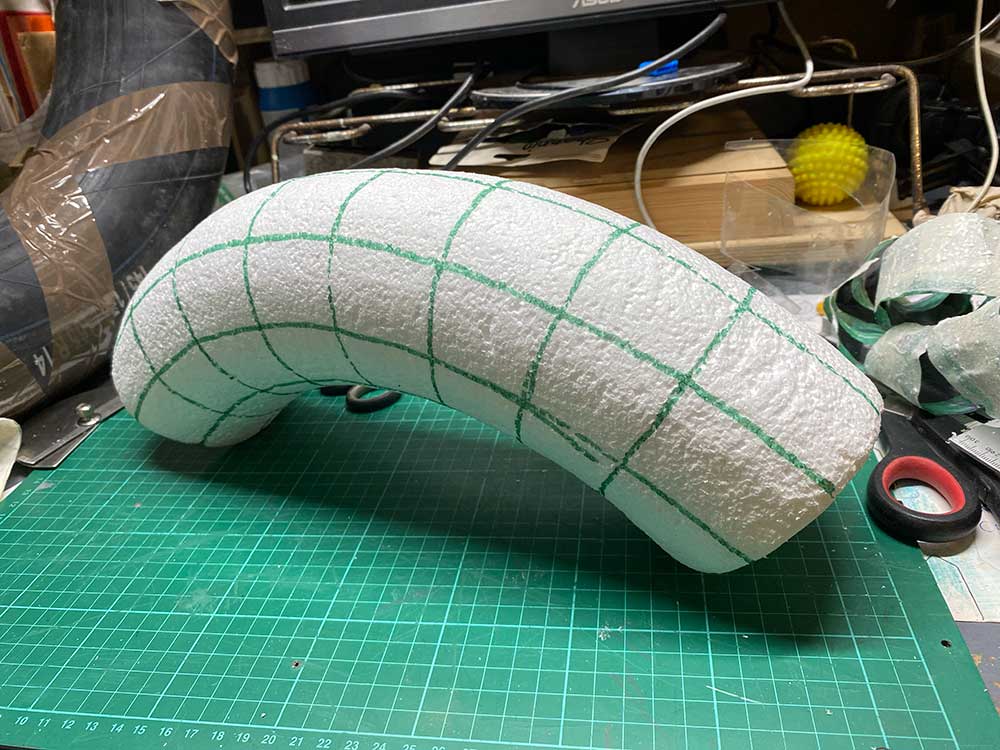

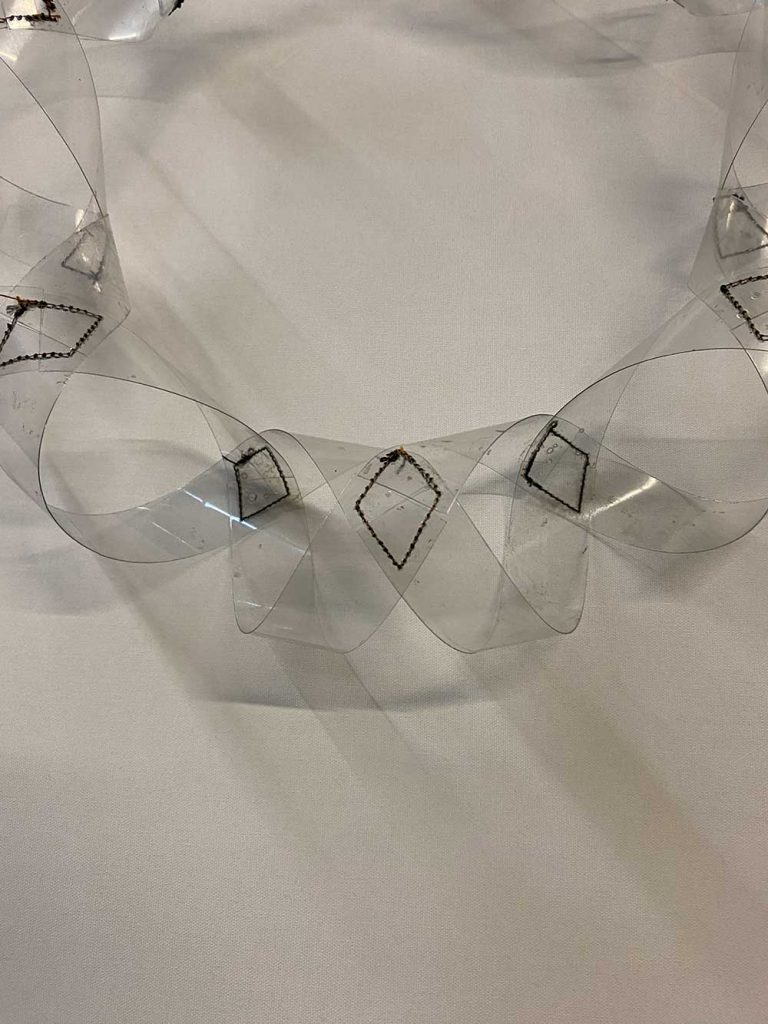

I gave up. A few times. Then this happened. Back in the game!

It is surprisingly hard to find a torus lying around the home or workshop! I just wanted to wrap some paper around a doughnut shape to see how it all played out. In the end I had to order online a tyre inner tube but when inflated it was too big and wonky. I had to make a quarter of a doughnut out of foam to work out how exactly the materials curved when the pieces were joined at 40.8º and 35.7º.

There’s a lot of suffering which is not apparent here. And a lot of downright silly assumptions about physical properties of strips of materials. Eventually, I learned – relearned for the millionth time – that each step brings one closer to a milestone though it’s unclear how many there are ahead.

Finally I was able to determine exactly where to punch the holes for the grommets.

But grommets did not work. The only option was stitching. Not grommets, not glue, not staples, not paperclips. Our beloved sewing machine saved the day.

The other concern was that I wanted to use as much of the recycled bottle as possible. The strip size was not determined by my aesthetic choices in the end but by the number of strips the bottles allowed to be cut out of them – 160mm and 100mm. I had to make the stripe length uniform otherwise it would take too long to make each wreath, pushing costs up. Around 30mm was as wide as I could go.

In any case, it was such a joy to discover that sweet spot. I was so anxious and eager to get a result that I can’t even remember the moment. I didn’t relax until I joined all the pieces together.

Now, I have the recipe, I can move on to other materials.

These prototypes are on display at our annual Blackhorse Workshop event where studio members put on display some of their output. Join us on Wednesday, 11 December 2024. Nice gifts. See you there.

And if you want one, get in touch.